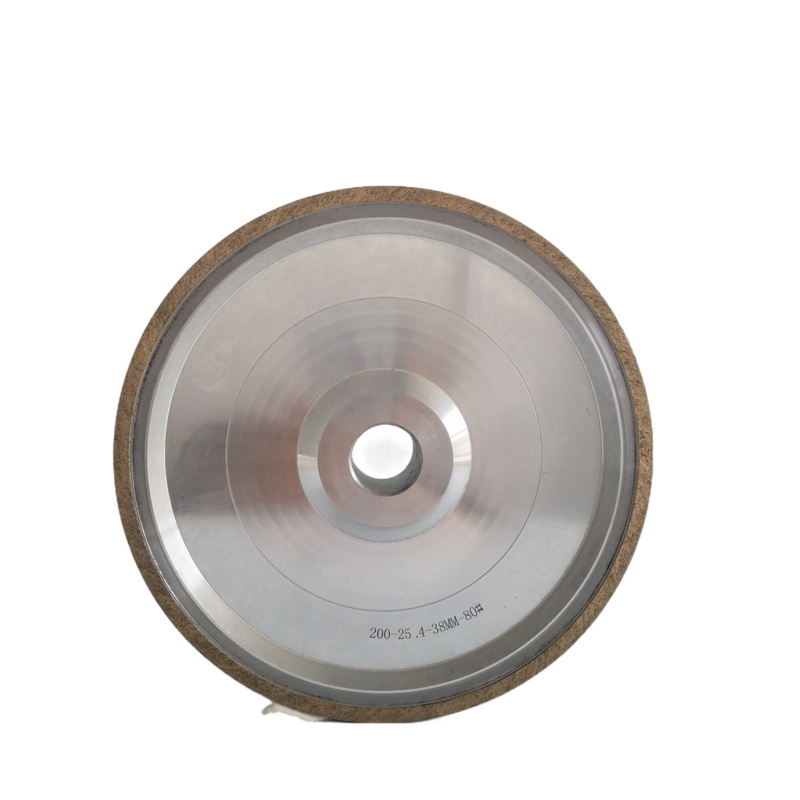

Sintered Metal Binder Diamond Grinding Wheel

1. Product parameters

| External Diameter(mm) | Thickness(mm) | Sand Width(mm) |

Mesopore(mm) |

|

150 |

38 |

5 |

25.4 |

|

150 |

50 |

5 |

25.4 |

|

200 |

28 |

5 |

25.4 |

|

200 |

38 |

5 |

25.4 |

|

200 |

50 |

5 |

25.4 |

Granularity: 40#, 60#, 80#, 120#, 180#, 200#, 280#, 360#, 400#, 600#, 800#, 1200#, 1500#, 2000#, etc.; Size can be designed according to customer's requirements.

2. Production of raw materials

Select imported high sharpness, high strength, high wear resistance diamond as abrasive.

3. Technology

Metal fastener is a type of sticky substance comprising of ultra solid material products manufactured with the help of metal or alloy dust as a bonding agent and a powder metallurgical technique for adding color. As an illustration, the bronze fastener utilizes bronze dust as the main metallic component and integrates additional metal dust such as tin, nickel, iron, silver, zinc, and lead to generate the sticky substance.

4. Product features

Finely polished, intricately carved, possessing a tough texture. Exhibiting a circular and sleek appearance, excellent concentricity, smooth grinding, and superior efficiency; representing a cost-effective alternative to comparable imported products.

5. Different from similar products on the market

Having considered the user's intended object for polishing, our technical staff will select the most suitable diamond model to serve as an abrasive. During the usage of our tools, customers have noted heightened grinding efficiency, prolonged lifespan, enhanced grinding outcomes, and the capability to supplant similar foreign products based on their cost performance.

6. Applied range

When it comes to the fabrication of monocrystalline silicon panels, we specialize in the grinding of sapphire, chamfering procedures, artistic stone engraving, and processing various mechanical components such as guide angles and grooves. Additionally, we also excel in the cleaning of pipes and the fine-tuning of inner holes and surfaces.